During Bundeswehr tank exercises, the heavy equipment becomes dirtied up, which has to be removed at a washing facility.

FRIESS is Fluid Cleaning Made in Germany. To that end we develop, design and manufacture equipment and systems with which you can clean your process fluids and maintain them.

FRIESS is Fluid Cleaning Made in Germany. To that end we develop, design and manufacture equipment and systems with which you can clean your process fluids and maintain them.

Optimize processes and reduce costs.

With us, you will find innovative solutions that minimize your operating costs and at the same time increase the productivity of your company. To meet the diverse needs of our customers we offer five product lines: oil skimmers, Magnetic Filters and Electrostatic Oil Cleaners, as well as a Oil Dewatering systems and Oil Separators.

Learn more

Mr. Oliver Benneck

Böttgerstr. 2

40789 Monheim am Rhein

Phone: +49 21 73 5 20 11 oder 5 20 12

Fax: +49 21 73 3 33 74

Mail: post@friess.info

Optical Valley International Building B510

Guandongyan Rd. No.2-2

Donghu New & High-tech Industrial Development Zone

CN-430074 Wuhan city, Hubei province

Phone: +86-27-87490195

Fax: +86-27-87490193

Mail: mail@oilskim-china.com

Web: www.friess.cn

Mr. Tomáš Kara-Ivanský

Sepekov 381

CZ-398 51 Sepekov

Phone: +42 07 37 18 19 49

Phone: +42 06 04 26 91 71

Fax: +42 02 72 77 24 00

Mail: info@4TEK.eu

Web: www.4TEK.eu

Mr. Kari Luhtala

Wolffintie 36 M10

FI-65200 Vaasa

Phone: +358 20 7 459 660

Fax: +358 20 7 459 667

Mail: kari.luhtala@fuchs.com

Web: www.fuchs.com/fi

Products: oil skimmer and Magnetic Filters

Mr. Kalle Kinnari

Kärkikuja 3

FI-01740 Vantaa

Phone: +358-10-8345-500

Fax: +358-10-8345-501

Mail: Kalle.Kinnari@masino.fi

Web: www.masino.fi

Products: Electrostatic Oil Cleaners

Mr. Aguera

31 ave. des lacs

FR-74950 Scionzier

Tel: +33-450183027

Fax: +33-450183028

E-Mail: md@mecadiffusion.net

Internet: www.mecadiffusion.com

John Wilson / Dan Norman

Unit 43, Equinox South Business Centre, Bradley Stoke

GB-BS32 4QL Bristol

Phone:+44-1792-277290

Fax: +44-1792-797707

Mail: john.wilson@amiad.com / dann@amiad.com

Web: www.amiad.com

Nick Foster

Wakefield WF2 7HZ

Phone: +44 (0)113 328 0330

Email: sales(at)friess.co.uk

Web: www.friess.co.uk

Mr. Themos Lykiardopoulos

Orfanidou 18

GR-111 41 Athens

Phone: +30 21 02 28 22 12

Fax: +30 21 02 02 55 14

Mail: info@stseurope.com

Web: www.stseurope.com

Mr. Robert Jakatics

Zsolt u. 8/A

HU-1016 Budapest

Phone: +36-1-225-8888

Fax: +36-36-1-225-8685

Mail: robert.jakatics@hskft.hu

Web: www.buvar-szivattyu.hu

Mr. Ajinkya Kelkar

Plot No. 7, Gat No. 281/1, Kasar Amboli

Tal. Mulshi

IN-412 111 Dist. Pune / Maharashtra, Code: 27

Phone: +91 7350003958

Mail: ifs@innovationfilter.com

Web: www.innovationfilter.com

Mr. Ivan Partono

E-Mail: ip@indo-europetrading.com

Phone: +31-692637116

Internet: indo-europetrading.com

Mr. G. Cappella / Mr. R. Pagano / Mr. G. Tanzi

Via Como, 69-A

IT-20031 Cesano Maderno (MI)

Phone: +39 03 62 57 51 54

Fax: +39 03 62 57 50 91

Mail: info@sepra.it

Web: www.sepra.it

Mr. Yuya Shimura

1-4-22 Yaesu Chuo-ku

JP-103-8680 Tokyo

Phone: +81-3-3278-6142

Fax: +81-3-3278-6147

Mail: shimura.yuya@moritani.co.jp

Web: www.moritani.co.jp

Mr. Vitaly Alexeev

Aptekarskij prospekt, 6 korpus A7

RU-197022 St.-Petersburg

Phone: +78 812 715 54 27

Fax: +78 812 740 76 37

Mail: nepspb@inbox.ru

Web: www.nepspb.ru

Mr. Xteven Teoh Hoe Seong

21, Jalan MJ 14

MY-47100 Puchong, Selangor

Phone: +60 3 80662496

Fax: +60 3 80626172

Mail: sales@xtstech.com

Web: www.xtstech.com

Mr. Oliver Benneck

Böttgerstr. 2

40789 Monheim am Rhein

Phone: +49 21 73 5 20 11 oder 5 20 12

Fax: +49 21 73 3 33 74

Mail: post@friess.info

ul. Krasickiego 44

PL-97-500 Radomsko

Kierownik Działu Filtracji / Filtration Department Manager:

Magdalena Pokrzywa

Mobil: +48 500 143 213

Pokrzywa@imponar.pl

Miłosz Gieroń

Doradca Techniczno-Handlowy/ Technical Sales Advisor

+48 500 143 125

Gieron@imponar.pl

Tel: +48 44 68 21 44 4

Fax: +48 44 68 20 82 0

E-Mail: imponar@imponar.pl

Internet: www.imponar.pl

Mr. Carlos Oliveira / Mr. Antonio Rodrigues

Estrada da Ponte de Antanhol, Lote A

PT-3041-575 Coimbra

Phone: +35 12 39 43 73 36

Fax: +35 12 39 43 86 19

Mail: friess.iberia@ventilaqua.com

Web: www.ventilaqua.com

Mr. Viktor Pachiu

256 Basarabia Blvd.

RO-73429 Bucharest-3

Phone: +40 21 2 55 10 81

Fax: +40 21 2 55 10 31

Mail: romarc@romarc.ro

Mr. Vitaly Alexeev

Aptekarskij prospekt, 6 korpus A7

RU-197022 St.-Petersburg

Phone: +78 812 715 54 27

Fax: +78 812 740 76 37

Mail: nepspb@inbox.ru

Web: www.nepspb.ru

Mr. Xteven Teoh Hoe Seong

21, Jalan MJ 14

MY-47100 Puchong, Selangor

Phone: +60 3 80662496

Fax: +60 3 80626172

Mail: sales@xtstech.com

Web: www.xtstech.com

Mr. Tomáš Kara-Ivanský

Sepekov 381

CZ-398 51 Sepekov

Phone: +42 07 37 18 19 49

Phone: +42 06 04 26 91 71

Fax: +42 02 72 77 24 00

Mail: info@4TEK.eu

Web: www.4TEK.eu

Mr. Carlos Oliveira / Mr. Antonio Rodrigues

Estrada da Ponte de Antanhol, Lote A

PT-3041-575 Coimbra

Phone: +35 12 39 43 73 36

Fax: +35 12 39 43 86 19

Mail: friess.iberia@ventilaqua.com

Web: www.ventilaqua.com

Hedenstorpsvägen 14

554 75 JÖNKÖPING

Phone: +46 36-12 47 10

Mail: kontakt@rotool.se

Web: www.rotool.se

Mr. Robert Peteri

Stensnäsvägen 4

SE-713 32 Nora

Phone: +46-587-15100

Fax: +46-587-15125

Mail: Robert@acmaskin.se

Web: www.acmaskin.se

Mr. Ulrich Ritter

Römerstraße West 49

CH-3296 Arch

Phone: +41 32 37 73 52 2

Fax: +41 32 37 73 52 4

Mail: info@rimann-ag.ch

Web: www.rimann-ag.ch

Mr. Allex Cheng

4F, N.O. 127, Sec. 3, Ren Ai Rd., Da An Dist.

TW-10656 Taipei City

Phone: +8 86-2-27 11-58 29

Fax: +8 86-2-27 11-61 39

Mail: allex@wellsuccesseng.com

Mr. Ratthawit Kij-areechote

104/2 Sukhaphiban 2 Road, Prawet

TH-10250 Bangkok

Phone: 0066-2329-2001

Fax: 0066-2329-2154

Mail: ratthawit@mte.co.th

Web: www.mte.co.th

Mrs. Birsen Alpartun

Büyükdere Cad.,Yapi Kredi Plaza, “C” Blok Kat: 18

TR-34330 Levent, Istanbul

Phone: +90-212-2783281

Fax: +90-212-2782884

Mail: b.alpartun@flogaz.com

Web: www.flogaz.com.tr

Mrs. Tatyana Kuzmenko

Borispolskaja str. 7, Room 225

UA-02099 Kiev

Phone: +380-44-3695177

Mail: tatyana@77lubricants.com.ua

Web: www.tansel.com.ua

Here you can find the contact details of our distribution partners in your region.

During Bundeswehr tank exercises, the heavy equipment becomes dirtied up, which has to be removed at a washing facility.

The oil-filled transformers were drained in order to get at the valuable raw materials inside. The drained oil collected in the collecting pans, which are meant to catch

Many manufacturing companies rely on coolant in their manufacturing processes. These coolants decrease the heat generated by friction in machining processes and also ...

One of the largest steel mills in Turkey was using another manufacturer's oil skimmer

A big manufacturer of components for engine and drive train uses a central emulsion tank with a volume of 30 m³ emulsion.

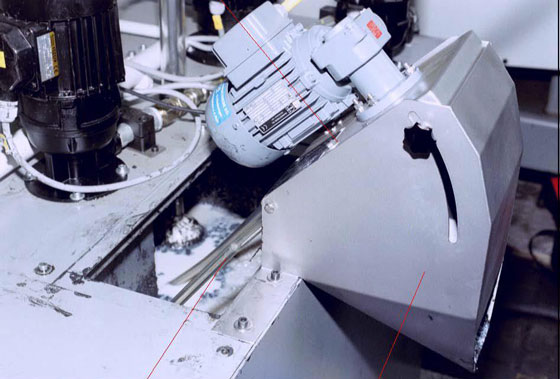

The company used an oil skimmer model 3H for more than 15 years in order to remove the oil from the washing water. The oil skimmer operated during the night shift.

The cooling water in a steel plant is contaminated with oil, fat and scale. In a settling basin, most of the scale sinks to the bottom of the basin. Oil, fat and a ...

A hot die casting company sprays a special high temperature release oil into their molds to facilitate removal of the finished injection molded parts. This mold ...

A chemical company is using palm oil to produce a laundry washing powder. When cleaning tanks or pipelines, the cleaning water became contaminated with palm oil, palm ...

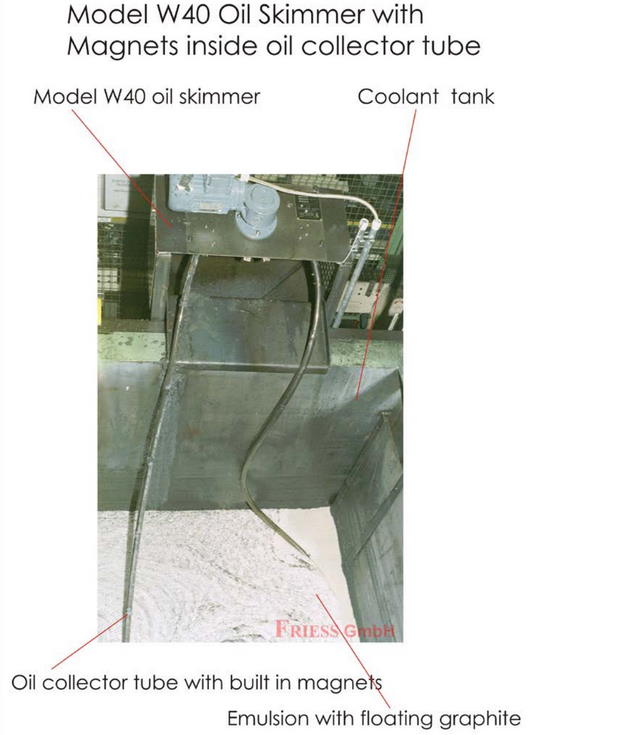

During machining of cast iron, metal chips and fine particles of carbon black and iron are produced. Bigger chips are removed by the filtration system while fine ...

In the production of biodiesel from rapeseed oil, it occurs that the crude oil as well as the final product gets into the waste water system. One such producer ...

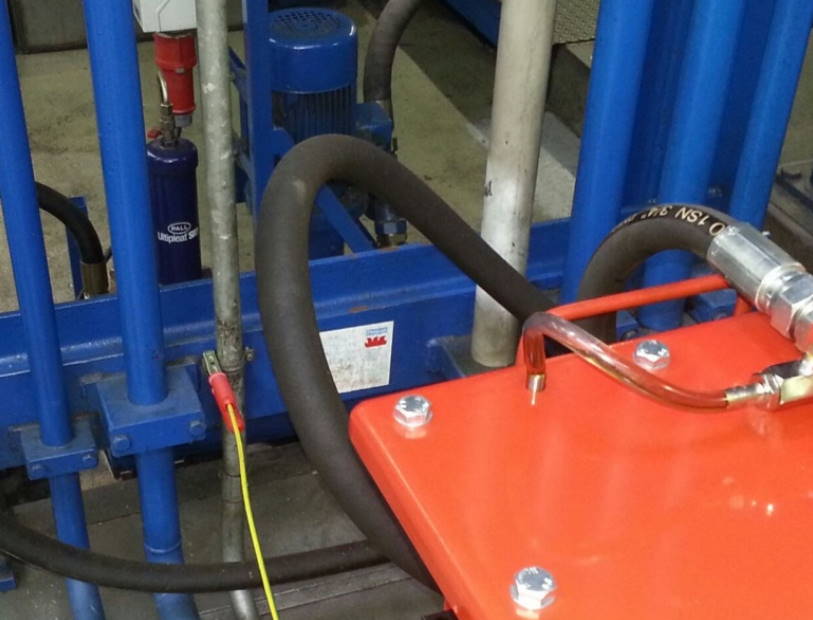

A well-known German Company that manufactures crankshafts for gasoline and diesel engines had ordered a new drop-forging press from a Japanese manufacturer.

Waste water of parking lots are not influenced by the dispersing effects of fast turning wheels and wind drift. Due to this

they can exhibit levels of HC concentratio ...

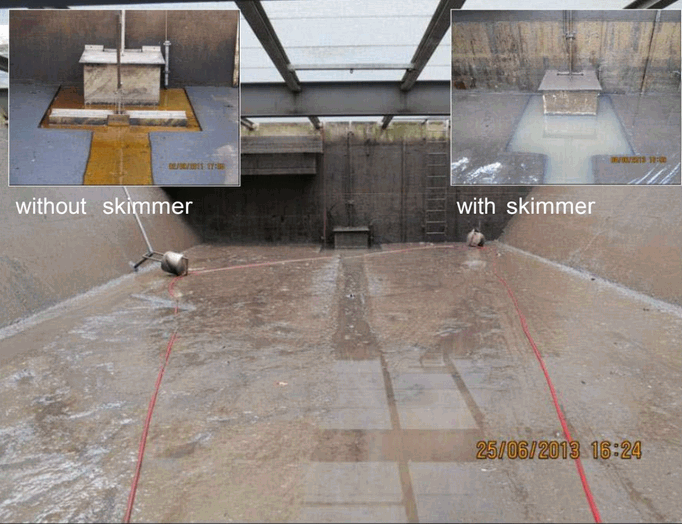

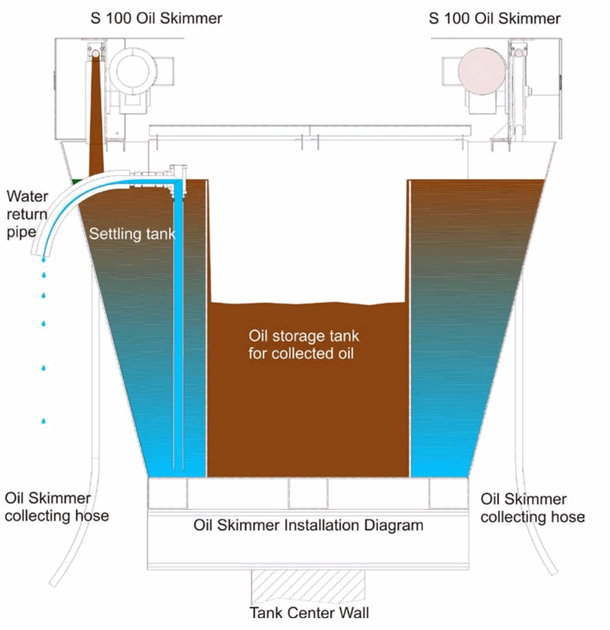

A metal working plant had two rectangular settling tanks with a common wall between them in operation. Every hour, 10 to 20 liters of oil become mixed with the ...

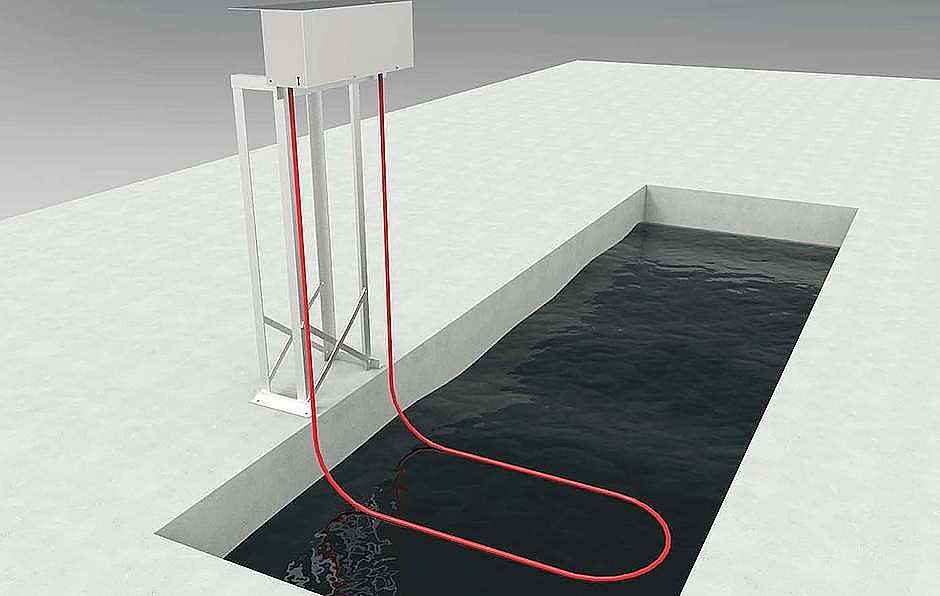

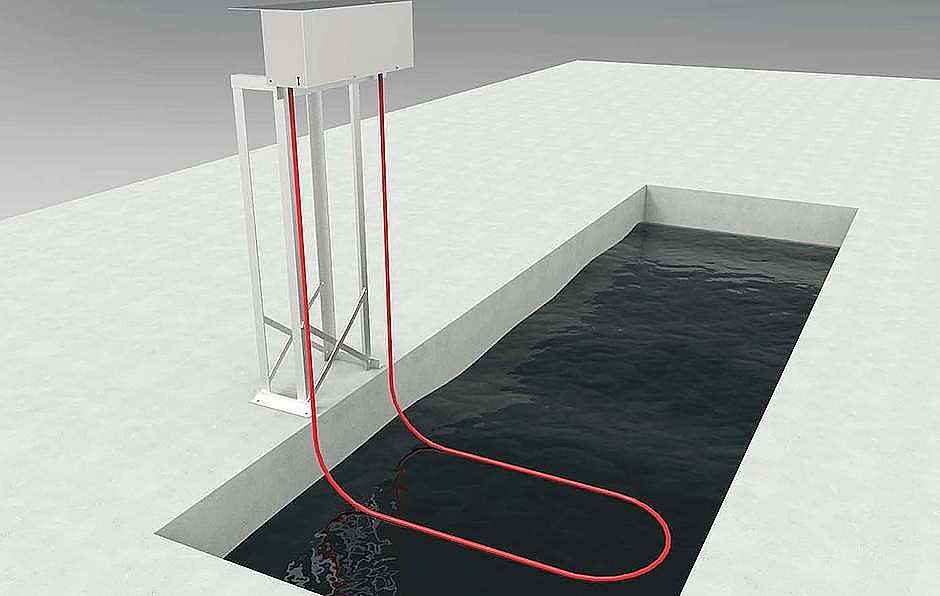

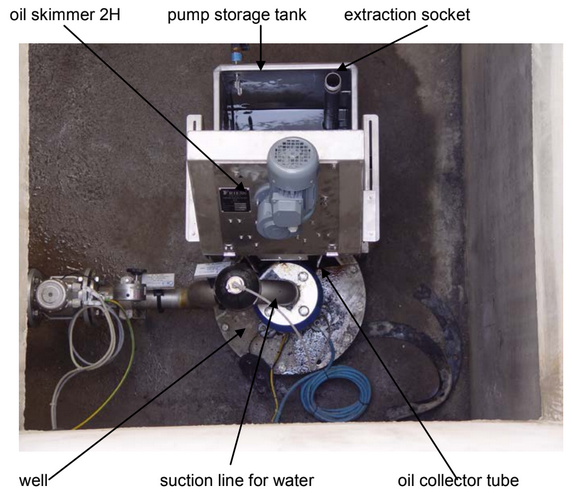

A FRIESS Oil Skimmer with oil collector tube replaced the belt oil skimmer. The floating oil, fat, and chemical sludge is removed from the entire surface by the ...

A milk processing company produces milk powder. In a vacuum evaporator, water is extracted from the milk. Approx. 15 % of the milk will be processed to milk powder.

The operator team of a big coolant separation system recognized after a longer period of operation that because of the higher content of oil in the delivered waste ...

A large manufacturer of printing machines uses approximately 300 machine tools to produce their parts. Each of these machine tools has its own coolant tank and filter ...

A manufacturer of automotive components uses different grinding machines in order to grind parts for steering systems.

The cooling water system at a steel rolling mill is heavily contaminated with tramp oil due to various oil leaks. Small amounts of oil and very viscous grease come from t

Casting iron parts are regularly machined at a production company. The chips produced in the process are flushed out of the machine by the cooling lubricant. Large chips

In the area around a refinery’s facilities the groundwater was suspected of being contaminated by hydrocarbons.

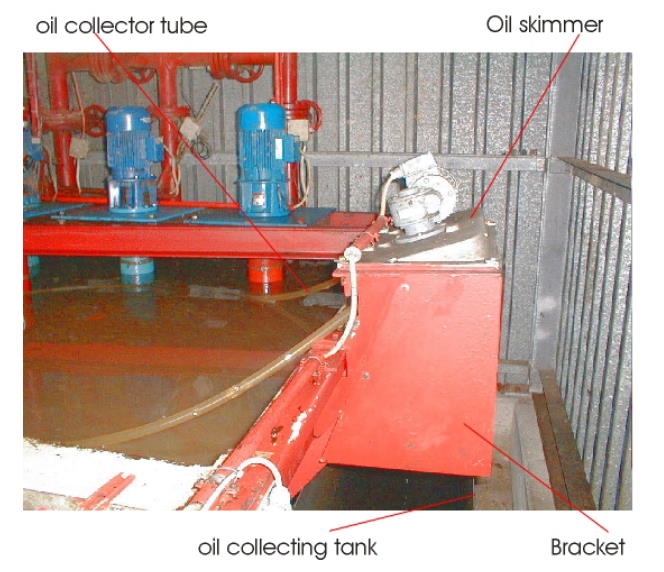

A rectangular clarifier tank at a steel factory was equipped with an oil skimmer with a floating oil pick-up mop to remove oil and grease from the cooling water surface.

A big manufacturer of packaging systems made of plastic uses 30 injection molding machines. The manufacturer of the injection molding machines recommends to change ...

A big European car manufacturer operates three factories for manufacturing gear boxes for passenger cars. One of the three factories in mid-Europe uses approx ...

Aluminum profiles are produced on big hydraulic extruding presses. The production process starts with round aluminum material. The hot aluminum is pressed by a ...

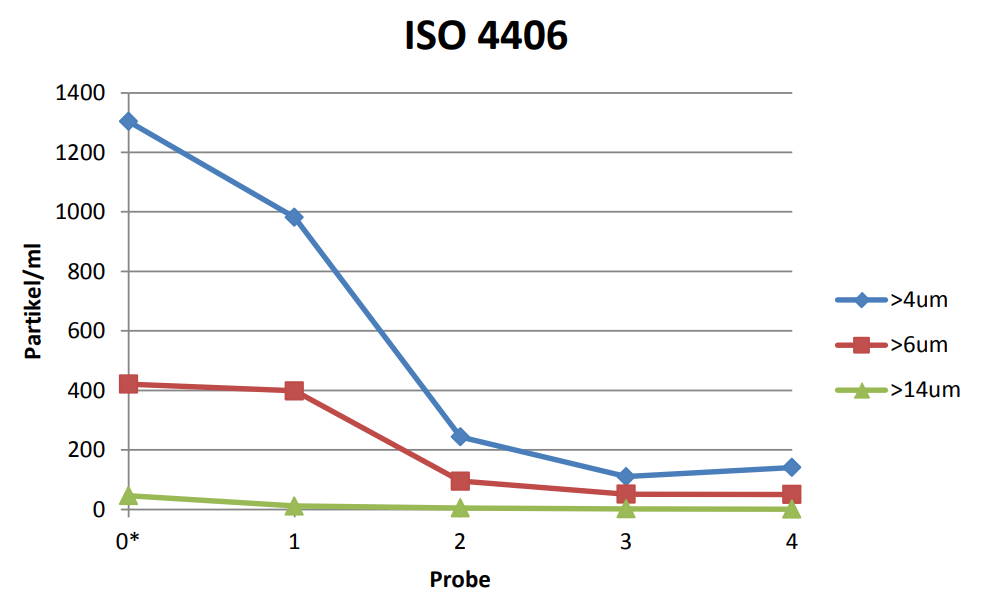

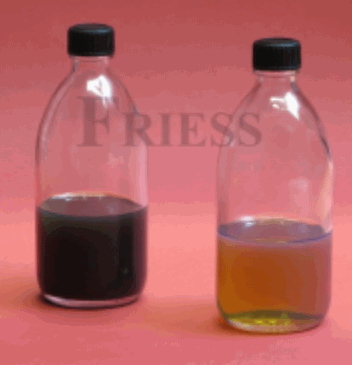

Before start up FRIESS sales manager took a sample of the hydraulic oil. After 300 h of operation of the electrostatic oil cleaning machine model D8 the FRIESS sales ...

A well-known global supplier to the automotive industry manufactures high-strength sheet metal parts for the automotive industry on state-of-the-art press lines in a ...

A metal working company produces pressure tanks with a volume of 50 l – 500 l. After machining the casted parts are washed in a part washing machine ...

In the Chinese plant of a big Japanese car manufacturer two honing machines are used in order to machine engine housings.

A metalworking company operates a washing machine in which hydraulic parts made from cast iron are washed to remove oil and grease as well as particle contamination ...

Zur Reinigung von Kühlwasser in Stahlwerken wird üblicherweise eine Kombination aus Sinterbrunnen, Längsklärbecken und anschließendem Kiesfilter eingesetzt.

On a railroad site for freight car storage, there are numerous tracks that are equipped with hydraulically operated brakes ...