FRIESS Oil Skimmers applied to Area Drainage

On a railroad site for freight car storage, there are numerous tracks that are equipped with hydraulically operated brakes to be able to brake out driverless freight car trains. Since these hydraulic systems are exposed to harsh environmental conditions as well as being under high pressure, it happens time and again that hydraulic hoses burst. Due to the size of the area, it often takes some time to find the leak and replace the hose.

- The problem

- The solution

- Control system with a GSM module

- more about FRIESS oil skimmers

In this time, however, the damage has already been done: Liters of hydraulic oil leak out of the ruptured hoses and enter the ground of the site. The ground is regularly contaminated with oil in this way, as this issue happens fairly frequently and has never been truly solved.

The problem

The result of this can be seen in the wastewater stream of the area. A certain film of oil can always be found in the separators of the drainage system. Under normal load, these separators can retain the oil before the water is discharged into the adjacent creek. The situation becomes problematic in the fall and winter, when rainfall occurs frequently, causing more hydraulic oil to be washed out of the ground and the water flow to increase. Particularly during heavy rainfall, such high volumes of water are generated that the separators can no longer hold back the oil, but it is carried along with the water and flows into the stream; with disastrous consequences for nature and the environment.

The solution to the problem: oil skimmer from FRIESS

To deal with this problem, the railroad company turned to a renowned company specializing in water projects in the field of environmental protection. They saw the potential for using an oil skimmer and turned to FRIESS.

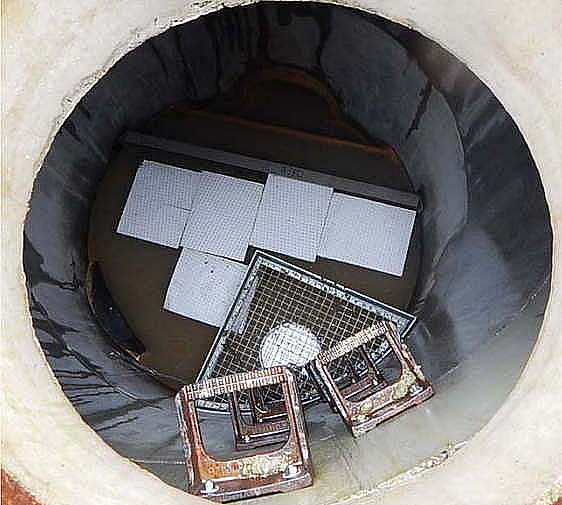

During the on-site inspection, the solution was worked out that an oil skimmer should be mounted on the oil separator so that the separated oil can be continuously discharged. This would prevent too much oil from being in the separator during heavy rainfall, which could be carried away with the large amounts of water.

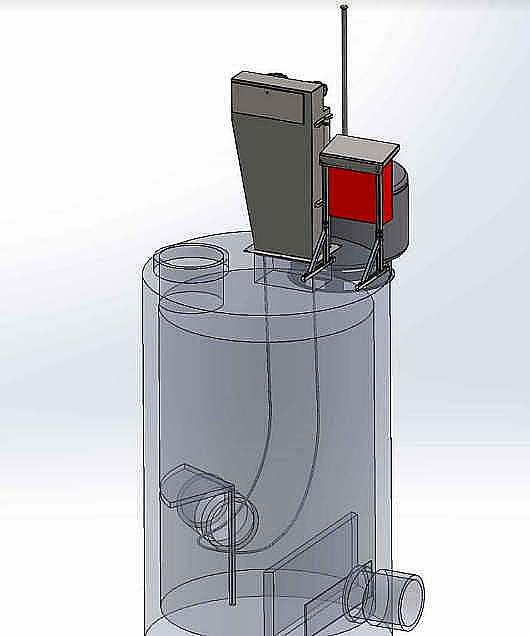

Control system with a GSM module to remotely control the oil skimmer

At the special request of the railroad company, the control system, which had been standard up to that point, was equipped with a GSM module to ensure communication between the system and the responsible persons without the need for an on-site visit, since the installation site of the oil skimmer is quite remote.

To ensure safe operation in winter and to avoid freezing, all relevant components were equipped with heating systems.