FRIESS oil skimmers remove floating oils and fats easily, quickly and reliably from all sorts of liquids.

Our oil skimmers remove oils and fats quickly and reliably. Use the FRIESS technology for liquids of all kinds – whether cooling lubricant, cooling water, degreasing agents or waste water.

What is the principle behind it?

The basis and at the same time the most important element is the oil collector tube. It generates a rotary motion on the surface of the bath, which sets the floating oil in motion. The oil is then picked up by the tube and transported to the oil skimmer. From there, it is in turn transferred to a waste oil collection tank. The result is a reliably oil-free liquid surface.

The advantages at a glance:

For almost 50 years

we have been finding solutions for cleaning process fluids.

More than 10K projects

have been realized and made customers happy all over the world!

Environmental balance

of our customers is demonstrably improved through FRIESS technologies.

Contents:

Oil adheres to a special oleophilic tube, which gets stripped off in the tube skimmer. The oil collector tube is hollow and thus floats on the liquid, operating precisely at the contact point of the two phases, the upper one being oil. Welded as an endless ring, the oil collector tube continuously removes oil from liquid surfaces, no matter how large. Since the tube can be sized as short or long as necessary, not only can smaller tanks be kept free of tramp oil, but also large cooling basins or ponds.

Wherever oil and grease accumulate where they do not belong and float on the contaminated liquid, an oil skimmer can be used to remove the tramp oils and greases. To a tube skimmer it does not matter how dirty the surroundings are or how viscous the oil is. Thus, any number of areas of application can be found:

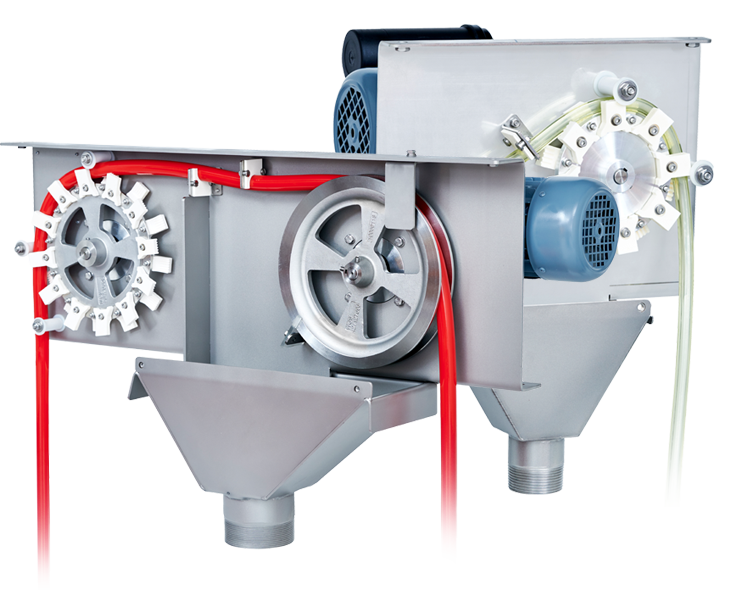

A belt skimmer consists of a motor with a drive roller and a mount. The drive roller drives a flat, endless belt, the skimmer belt. A loose pulley roller pulls the belt downward. The lower part of the belt is immersed in the floating oil phase. The oil adheres to the skimmer belt and is then moved into the water below. The oil still adhering to the belt is then conveyed upwards and removed from the belt by the scrapers.

Belt skimmers are mostly used for cooling lubricant applications in metalworking. Especially for the small coolant tanks of smaller machine tools, these small skimmers are very popular. The usually fairly small capacity of belt skimmers often suffices to remove the small amounts of tramp oil found in coolant tanks.

From time to time, belt skimmers are also used for oil removal in smaller oil separators. However, it is important to pay attention to the size of the separator, as belt skimmers cannot keep large areas free from oil and are only intended for really small applications.

Oil separators and oil skimmers are not identical. Both forms of oil removal take advantage of the difference in density between oil and water. The basic difference is that the oil separator retains the floating oils and greases by means of baffles, while the oil skimmer continuously removes the floating oils from a preexisting tank.

Oil separators consist of a tank through which a liquid is pumped and settled so that the oil or grease it contains can rise to the surface. Often, coalescing packages are installed in an oil separator to improve the separation process. A baffle prevents the oil or grease from leaving the separator, as this now floats to the top and cannot flow under the baffle.

An oil skimmer, on the other hand, removes the already floating oil from a liquid surface.

Thus, although an oil skimmer and an oil separator have similar objectives, they are used in different conditions.

Often, oil separators and oil skimmers can be combined to have the advantages of both systems. For example, the oil separator is used to settle the liquid when this cannot happen elsewhere in the system. The oil skimmer removes the accumulated oil from the oil separator so that it does not contain too much oil, which could result in the oil bypassing the baffle. This is the procedure we use with our Skimmtelligent oil separators. These are used when the liquid is too turbulent for an oil skimmer and the oil does not float on the surface.

Since 1972 we have been developing and producing oil skimmers Made in Germany for a wide range of requirements and industries. From consulting, manufacturing and sales, if necessary also on-site assembly, we are at your disposal. In addition, we offer other options for oil-water separation, the maintenance of cooling lubricants and oil cleaning. With us, environmental protection and cost savings go hand in hand.

Before you buy an oil skimmer, we have a questionnaire for you. This provides us with important information. We will gladly send you this as a PDF on request. Important factors for us are:

As a rule, we deliver our oil skimmers within one week. They are easy and self-explanatory to install, so that only in individual cases it is necessary to resort to our installation services.

With the tube of the tube skimmer floating on the surface, the floating oily or greasy film is skimmed off from all parts of the surface of the tank by the constant rotary movement on the fluid surface. The film is literally drawn in, so that there are no areas in a tank where the oil film is not reached. The belt skimmer does not offer this advantage. In addition, the oil collector tube can be made as long as necessary to cover the entire length or width of a tank, resulting in maximum oil removal.

A belt skimmer cannot achieve this effect with its skimmer belt, and thus takes far more time to achieve the same result. In fact, it is often the case that despite the work of the belt skimmer, a comparable result is not achieved, as this type of oil skimmer cannot remove tramp oil from such large areas.

Industrial wastewater – important facts

Requirements for the purification and disposal of wastewater

In addition to safety precautions, companies that generate wastewater must also provide a system that enables the recycling of wastewater. The substances with which wastewater is contaminated depend on the industry. For contaminants that float on the water surface, FRIESS GmbH offers oil skimmer and oil separator solutions for wastewater treatment Made in Germany. Fats and oils are reliably and properly removed, so that the subsequent treatment of the wastewater is easier, and does not require so many chemicals to achieve the prescribed contamination values for the discharge of wastewater.

You will need to check with your local municipality to determine exactly which values are required to discharge your wastewater, as they often vary by region. Regardless, oil skimmers simplify the treatment of oily wastewater and allow you to meet discharge limits with less effort.

Its use often helps to extend the service life of a fluid. In the case of cooling lubricants and washing water, the removal of tramp oils helps to extend the period during which the fluid meets the specified parameters necessary for its function. This means that the fluid needs to be changed less frequently and the usage duration is increased.

This saves raw materials used in making process fluids and reduces the burden on the company’s waste disposal. Because the longer a fluid can be used, the more efficiently raw materials are used. This results in increased sustainability, which benefits the environment because fewer chemicals or oils have to be used and disposed of.

They are particularly durable. This means that maintenance is inherently low-cost. In addition, the oil skimmers do not require much maintenance and attention. Therefore, maintenance staff need to spend little time and effort with them and can focus on other, more pressing, tasks

Furthermore, an oil skimmer improves your manufacturing process by using cleaner fluids, such as cooling lubricants. In such an application, expensive defects can be avoided.

Oil and grease removed by oil skimming is usually disposed of. Depending on the water content, the disposal company may pay for the oil.

However, if the oil or grease is too contaminated, disposal usually must be paid for.

Processing the oil for reuse is possible, but often involves high expenses. Weighing up the costs and benefits is essential here.

Increasing the service life of fluids by removing tramp oil, allows you to use these fluids in your machines longer. These fluids then do not need to be procured as frequently. This saves money in purchasing!

FRIESS oil skimmers for oil removal are standardly made from high-quality materials such as stainless steel and ceramics. This means they can be used in a wide variety of applications without needing to worry about corrosion or other wear and tear. For particularly aggressive environments, such as very acidic applications, e.g. the use of acids, or very alkaline applications, e.g. alkaline cleaning processes, other materials may have to be used. In this case, we can also manufacture the oil skimmers in higher quality stainless steel (SS316) or plastics. This way, we can cover almost the entire pH value spectrum.