High Tramp Oil Contamination in Cooling WaterOil removal from cooling water used in a cold rolling process in a steel mill is improved with the use of a friess oil skimmer

One of the largest steel mills in Turkey was using another manufacturer’s oil skimmer (Oil Skimmer Inc. Model 6V) in a cooling water settling basin of a cold rolling mill, but they were not satisfied with either the performance or the on-site service. A more efficient and low maintenance solution was needed to effectively remove floating oil from the surface of the cooling water.

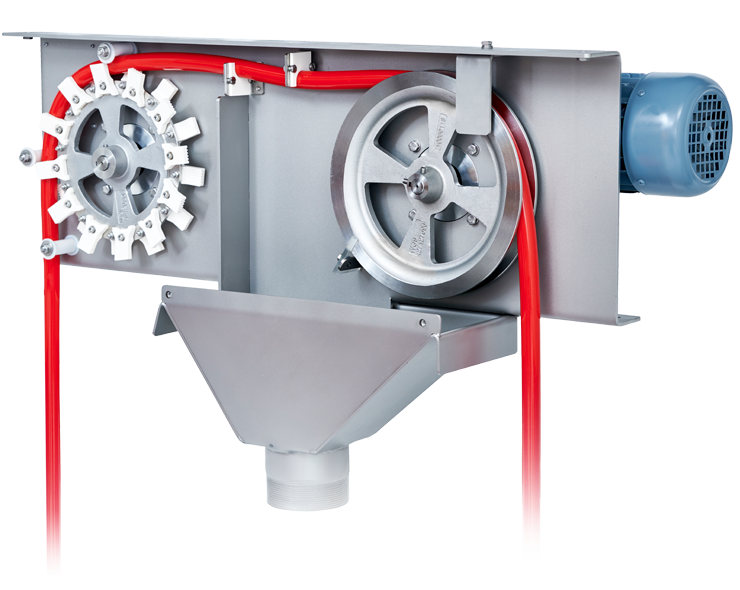

Solution: Friess Oil Skimmer S 100

Our distributor in Turkey contacted the steel plant and presented the FRIESS product portfolio. In particular, the FRIESS oil skimmer S 100, as it has proven itself many times in the removal of heavy tramp oil contamination of the cooling and waste water in steel manufacturing despite high dirt loads, as had been shown at other plants of this steel group.

After establishing a trusting relationship and because FRIESS’ experience of high performance oil skimmers in steel plants, the decision was made to purchase the model S 100. Moreover, as the customer was in the process of modernization and automation optimization of the water systems, the S 100 oil skimmer was purchased as an essential part of the water treatment.

Friess S 100 above the settling basin

Opening in the cover of the settling basin

Friess Oil Skimmer during commissioning

Tramp oil is removed by FRIESS S 100

Result

The performance of the S 100 was already evident during commissioning, which was very satisfying for the customer.

The on-site support provided by the FRIESS distributor was also very well received by the company’s technicians.

Specific figures on the improvement in the quality of the cooling water have not yet been collected, but the visual results speak for themselves.

By using the FRIESS oil skimmer, tramp oil from the production process is now removed continuously and reliably.

This improves the water quality of the cooling water and relieves the downstream systems. Thus, sustainability and cost reduction go hand in hand in this case as well. Due to the high-quality materials and simple operation of the S 100, the customer benefits from an oil skimmer that is low-maintenance and durable.

Summary:

- Process optimization through reliable oil removal

- easy operation and low maintenance

- first-class customer service with immediate results