FRIESS S 100 Oil Skimmerused in the Chemical Industry

A chemical company is using palm oil to produce a laundry washing powder. When cleaning tanks or pipelines, the cleaning water became contaminated with palm oil, palm fat, and other oils. The oily waste water was collected in a tank, 1.8 meters wide and 6 meters long.

The Problem:

To remove the oil and the fat from the cleaning water, the company had mounted a floating funnel, adjustable for the varying water height, in the tank. The oils and fats were scraped into the funnel by hand. The oil and fat was then pumped into a collecting tank. Because the adjustment of the funnel was difficult, the oil waste pump pumped 80 % water. A large quantity of the oil and fat in the tank was not removed. The cleaning water still contained too much oil and fat. The company searched for a better method to separate the oil and fat from the cleaning water.

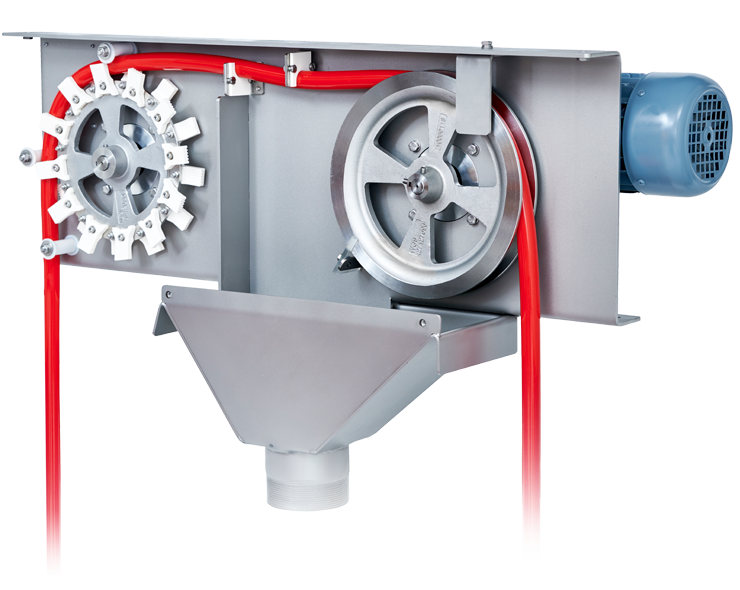

The Solution: FRIESS Model S 100 Oil Skimmer

To remove the oil-fat mixture from the tank, a FRIESS Model S 100 Oil Skimmer was installed. Even though the cleaning water had a temperature of 60 degrees C the fat was still very hard. When the Oil Skimmer initially started operating, a fat layer approximately 10 cm thick was floating on the water surface. As the skimmer started operation, the oil collector hose initially created a 5 cm wide opening in the fat layer. Within a short operating time, the FRIESS S 100 Oil Skimmer had removed all the oil and fat from the water surface.

Although the pipeline from the oil skimmer to the collecting tank was 10 cm in diameter, it soon became clogged by all the fat. After adding heating to the pipeline, the FRIESS S 100 Oil Skimmer reached a capacity of more than 200 liters of oil removal per hour, and in a short time, the oil-fat layer was completely removed from the water surface. To achieve a higher removal rate, the gear ratio of the gear motors was changed from 40:1 to 25:1 in order to increase the speed of the oil collector tube. The discharge line from the oil skimmer to the collection tank was now nearly vertical, so that the removed oil-fat could fall directly into the collection tank.

The Result:

The FRIESS S 100 Oil Skimmer reduced the amount of residual oil and fat in the cleaning water by more than 50 %. By pre-treating the cleaning water with the FRIESS S 100 oil skimmer, the final waste water could now be treated easily so that it conformed to German waste water discharge standards.

Because of the positive results the company achieved with the FRIESS S 100 S Oil Skimmers, additional FRIESS S 100 Oil Skimmers have been purchased and are now in operation at the company.