Electrostatic Oil Cleaning in a test standFRIESS-EFC D4 cleans hydraulic oil

A metal working company produces pressure tanks with a volume of 50 l – 500 l. After machining the casted parts are washed in a part washing machine. After washing the parts are tested with hydraulic oil HLP 32 in order to test leak tightness. The company uses three test stands. Each test stand is filled with 2000 l hydraulic oil. Each tested tank carries small amount of oil out of the test stand. For this reason the company does not change the oil, but adds regularly new oil to the test stand.

Situation

Although the company uses conventional filters in order to clean the oil, they found out, that there are lots of small dirt particles in the oil.

Customers complained about dirt particles inside the tanks. The quality management found out, that the reason for the particles inside the tanks is the dirty test oil.

Solution

The company uses high grade fine filters in order filter the test oil. In order to improve the cleanliness of the test oil, the maintenance manager and quality manager were looking for an alternative cleaning method. From his primary activities the maintenance manager remembered the good experience with FRIESS EFC electrostatic oil cleaning machines. For this reason the company decided to install electrostatic oil cleaning machine model D4 in order to clean the test oil.

FRIESS EFC D16 electrostatic oil cleaning machine D16 at hydraulic extruder

FRIESS EFC D16 electrostatic oil cleaning machine D16 at hydraulic extruder

FRIESS EFC electrostatic fluid cleaner model D4

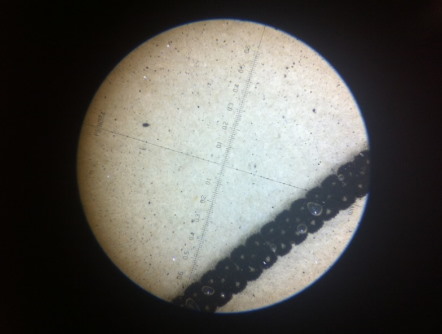

During start-up of the electrostatic oil cleaner the maintenance manager took an oil sample. Because of the extreme contamination of the oil with particles and especially with oxidation products, we could only filter 10 ml instead of the normal 30 ml of oil through the test membrane. All pores of the membrane (pore size 0.8 µm) were blocked after 10 ml of oil had passed the membrane. Because of the extreme contamination and the continuous input of new particles, we recommended a cleaning time of min. 3 months.

result

Test membrane after filtration of 10 ml oil

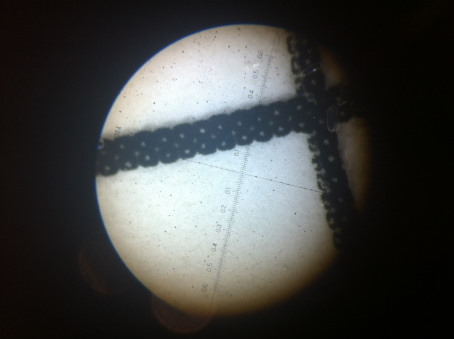

Already after two weeks cleaning time, the cleanliness of the oil was improved drastically. Oxydation products in the oil were reduced obviously. In addition to that the number of bigger particles was reduced considerably.

After electrostatic oil cleaning, Test membrane after filtration of 30 ml oil

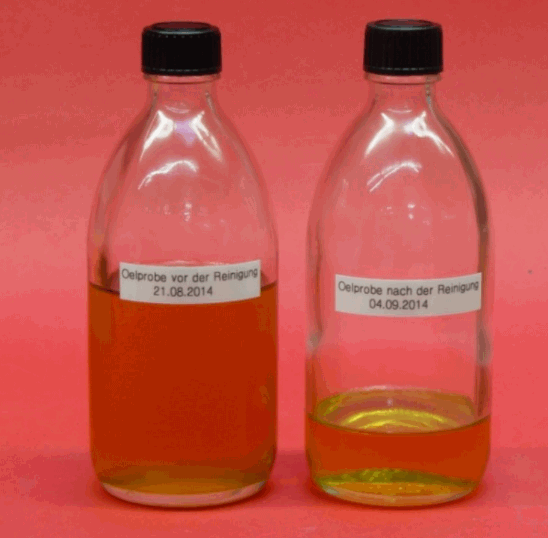

The explicit improvement of the cleanliness of the oil can be seen directly when comparing both oil samples.

Oil sample before and after cleaning with FRIESS EFC D4

Because of the excellent cleaning results the management decided to equip each test stand with one electrostatic oil cleaner model D4. In addition two electrostatic oil cleaners model D2 are now used in order to clean the hydraulic oil in the machine tools.