During Bundeswehr tank exercises, the heavy equipment becomes dirtied up, which has to be removed at a washing facility.

During Bundeswehr tank exercises, the heavy equipment becomes dirtied up, which has to be removed at a washing facility.

The oil-filled transformers were drained in order to get at the valuable raw materials inside. The drained oil collected in the collecting pans, which are meant to catch

Many manufacturing companies rely on coolant in their manufacturing processes. These coolants decrease the heat generated by friction in machining processes and also ...

One of the largest steel mills in Turkey was using another manufacturer's oil skimmer

A big manufacturer of components for engine and drive train uses a central emulsion tank with a volume of 30 m³ emulsion.

The company used an oil skimmer model 3H for more than 15 years in order to remove the oil from the washing water. The oil skimmer operated during the night shift.

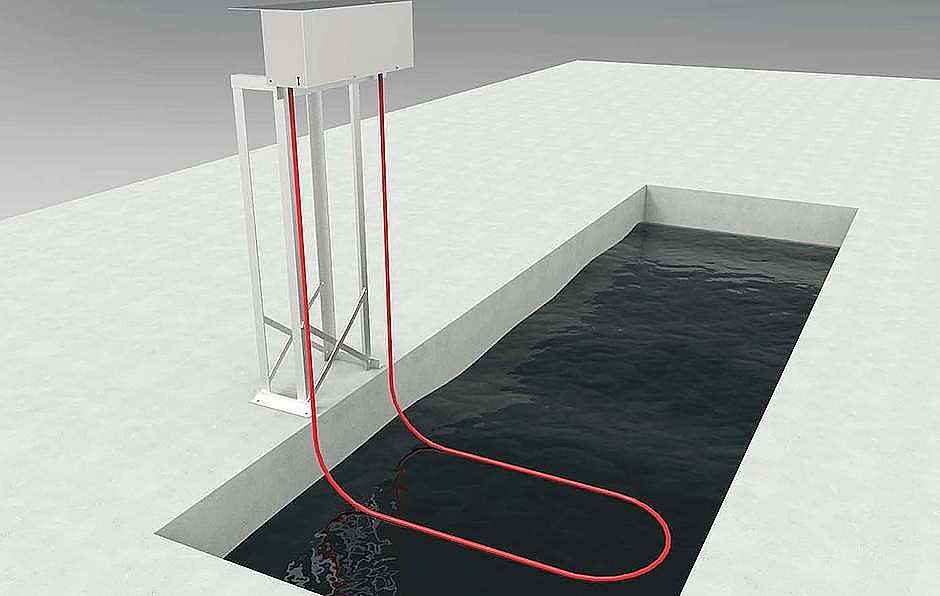

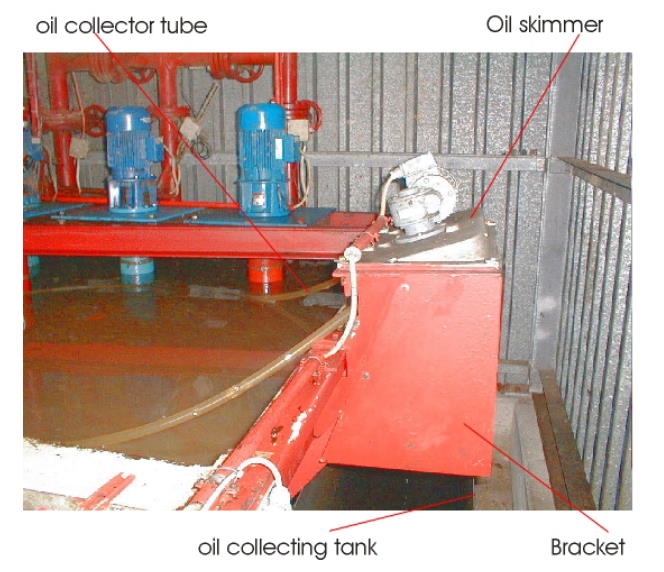

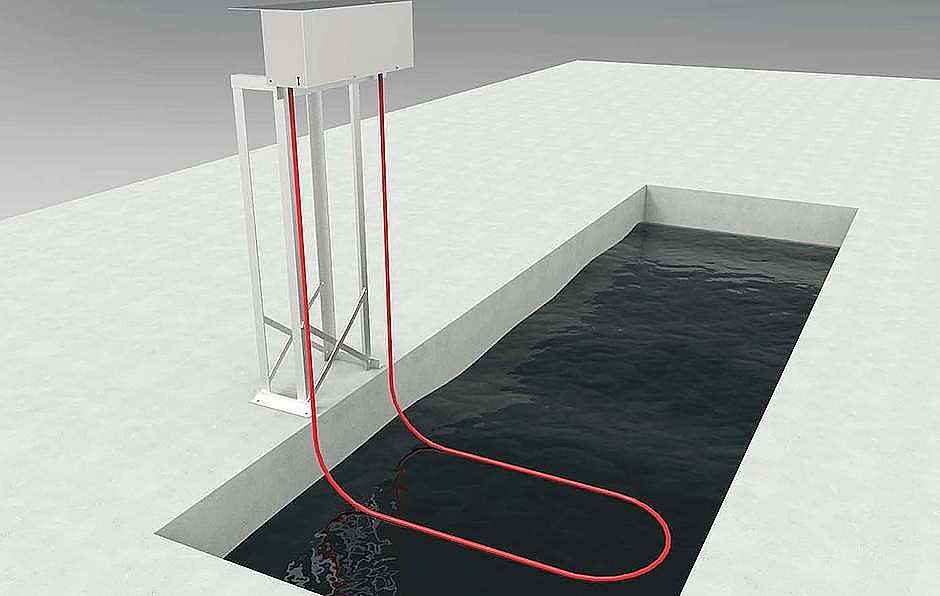

The cooling water in a steel plant is contaminated with oil, fat and scale. In a settling basin, most of the scale sinks to the bottom of the basin. Oil, fat and a ...

A hot die casting company sprays a special high temperature release oil into their molds to facilitate removal of the finished injection molded parts. This mold ...

A chemical company is using palm oil to produce a laundry washing powder. When cleaning tanks or pipelines, the cleaning water became contaminated with palm oil, palm ...

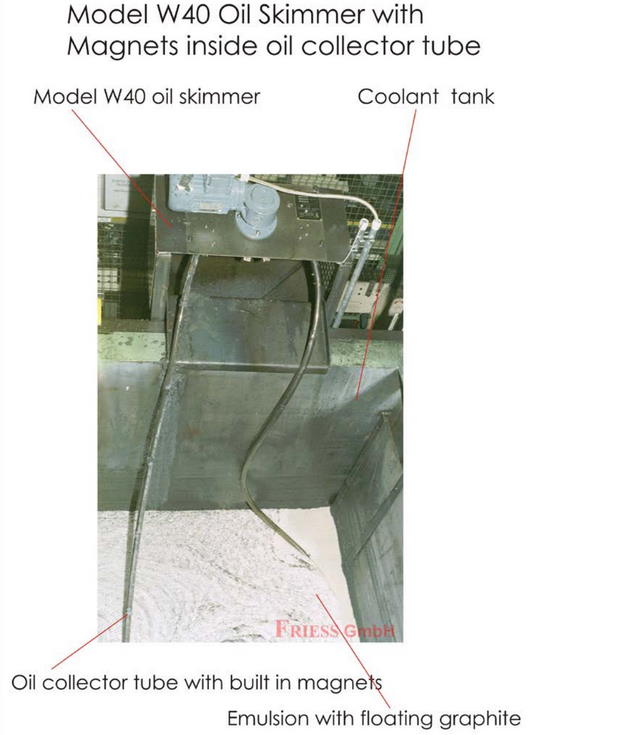

During machining of cast iron, metal chips and fine particles of carbon black and iron are produced. Bigger chips are removed by the filtration system while fine ...

In the production of biodiesel from rapeseed oil, it occurs that the crude oil as well as the final product gets into the waste water system. One such producer ...

A well-known German Company that manufactures crankshafts for gasoline and diesel engines had ordered a new drop-forging press from a Japanese manufacturer.

Waste water of parking lots are not influenced by the dispersing effects of fast turning wheels and wind drift. Due to this

they can exhibit levels of HC concentratio ...

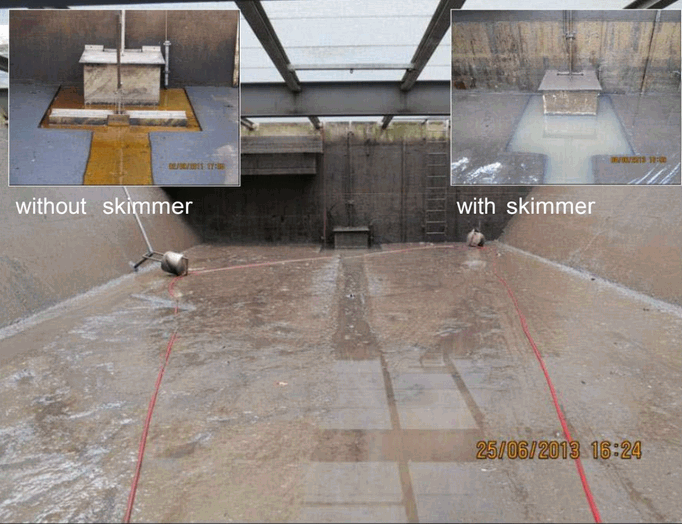

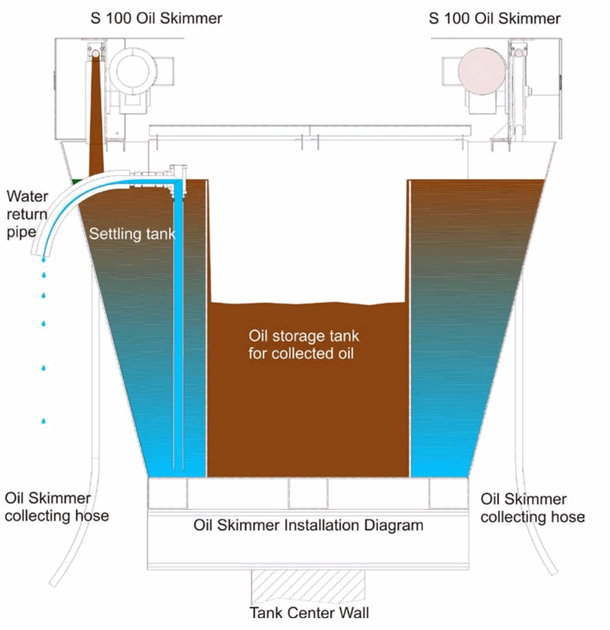

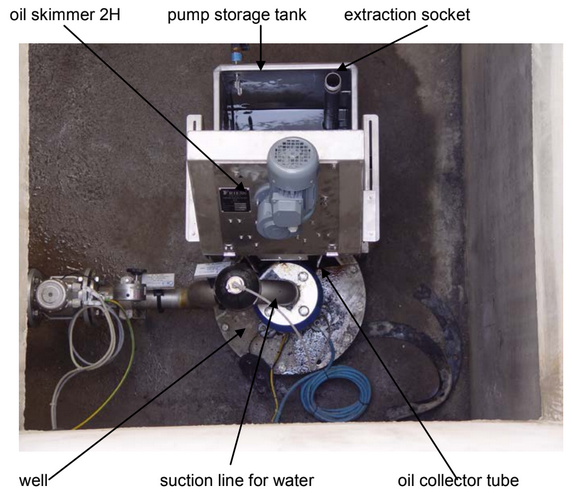

A metal working plant had two rectangular settling tanks with a common wall between them in operation. Every hour, 10 to 20 liters of oil become mixed with the ...

A FRIESS Oil Skimmer with oil collector tube replaced the belt oil skimmer. The floating oil, fat, and chemical sludge is removed from the entire surface by the ...

A milk processing company produces milk powder. In a vacuum evaporator, water is extracted from the milk. Approx. 15 % of the milk will be processed to milk powder.

The operator team of a big coolant separation system recognized after a longer period of operation that because of the higher content of oil in the delivered waste ...

A large manufacturer of printing machines uses approximately 300 machine tools to produce their parts. Each of these machine tools has its own coolant tank and filter ...

A manufacturer of automotive components uses different grinding machines in order to grind parts for steering systems.

The cooling water system at a steel rolling mill is heavily contaminated with tramp oil due to various oil leaks. Small amounts of oil and very viscous grease come from t

Casting iron parts are regularly machined at a production company. The chips produced in the process are flushed out of the machine by the cooling lubricant. Large chips

In the area around a refinery’s facilities the groundwater was suspected of being contaminated by hydrocarbons.

A rectangular clarifier tank at a steel factory was equipped with an oil skimmer with a floating oil pick-up mop to remove oil and grease from the cooling water surface.

Zur Reinigung von Kühlwasser in Stahlwerken wird üblicherweise eine Kombination aus Sinterbrunnen, Längsklärbecken und anschließendem Kiesfilter eingesetzt.

A big manufacturer of packaging systems made of plastic uses 30 injection molding machines. The manufacturer of the injection molding machines recommends to change ...

A big European car manufacturer operates three factories for manufacturing gear boxes for passenger cars. One of the three factories in mid-Europe uses approx ...

Aluminum profiles are produced on big hydraulic extruding presses. The production process starts with round aluminum material. The hot aluminum is pressed by a ...

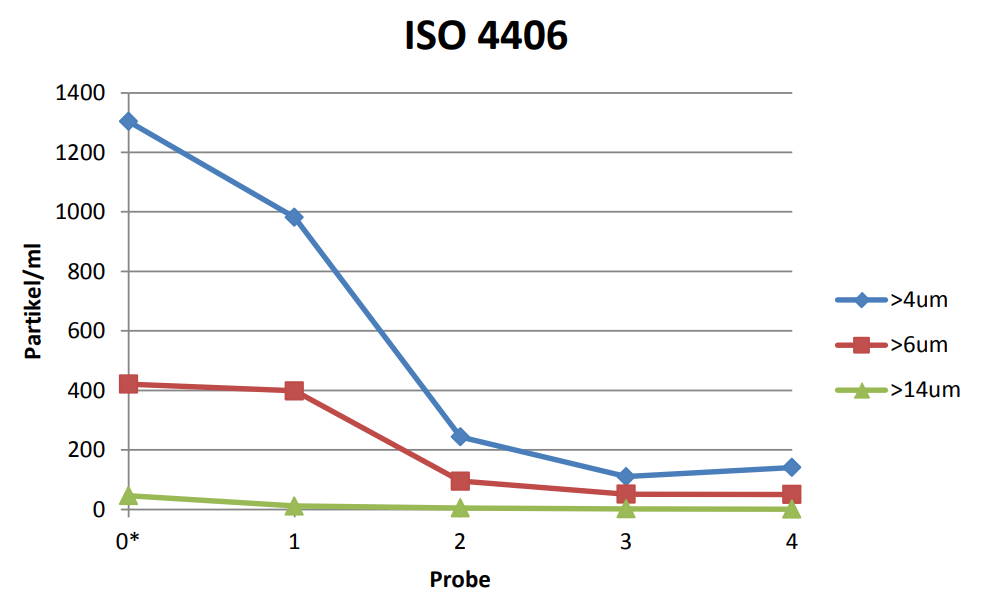

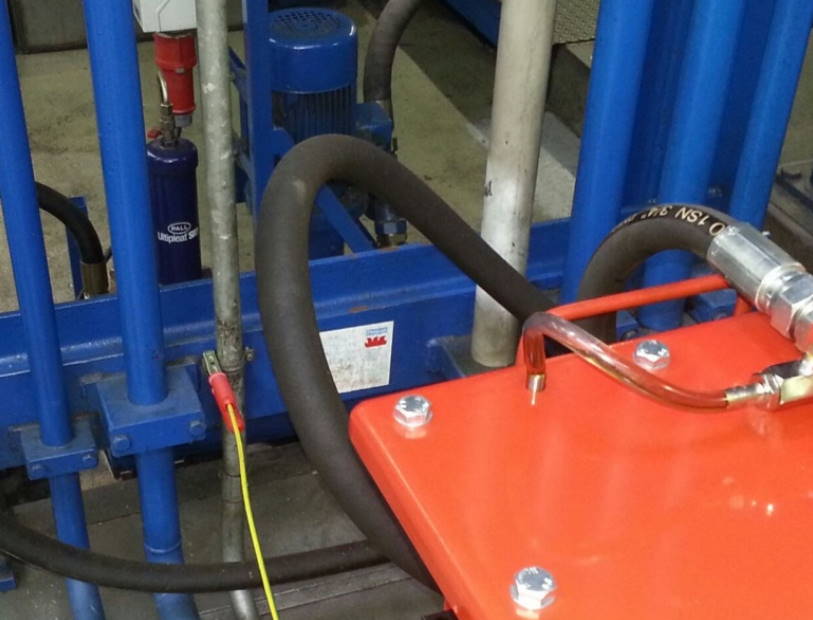

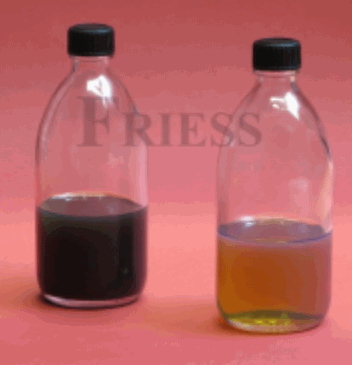

Before start up FRIESS sales manager took a sample of the hydraulic oil. After 300 h of operation of the electrostatic oil cleaning machine model D8 the FRIESS sales ...

A well-known global supplier to the automotive industry manufactures high-strength sheet metal parts for the automotive industry on state-of-the-art press lines in a ...

A metal working company produces pressure tanks with a volume of 50 l – 500 l. After machining the casted parts are washed in a part washing machine ...

In the Chinese plant of a big Japanese car manufacturer two honing machines are used in order to machine engine housings.

A metalworking company operates a washing machine in which hydraulic parts made from cast iron are washed to remove oil and grease as well as particle contamination ...

On a railroad site for freight car storage, there are numerous tracks that are equipped with hydraulically operated brakes ...