Tramp Oil on Waste WaterA FRIESS Oil Skimmer with oil collector tube replaced the belt oil skimmer.

At a plant making chemical products, different waste water streams were collected in a small tank. This tank had dimensions of 1.5 m X 1.5 m, and was installed below ground level. A pump, pumped the waste water from the below ground collection tank into the waste water treatment facility.

The Problem

Different types of oils and fats floated on the surface of the tank. In addition to used lubrication oils, chemical products which are produced at the company also floated on the water surface. To remove the oil, fat, and chemical sludge the company used a belt skimmer. The belt skimmer was equipped with a stainless

steel belt. Because of the high maintenance costs of the system – 3.068 € per year – and the low capacity, the maintenance deparment looked for a better system.

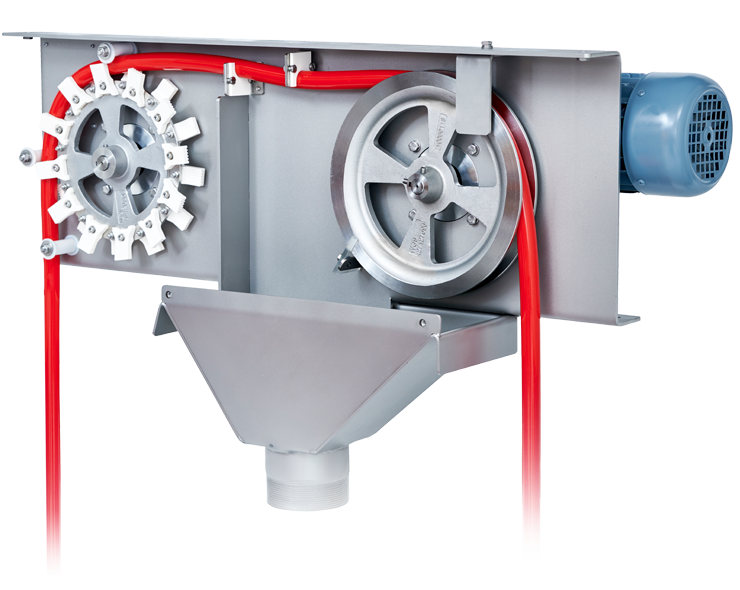

The Solution: A FRIESS Oil Skimmer

A FRIESS Oil Skimmer with oil collector tube replaced the belt oil skimmer. The floating oil, fat, and chemical sludge is removed from the entire surface by the floating oil collector tube, after which it flows via an open chute to a second tank, where the oil, fat and sludge is collected. Very sticky products may also be separated by the oil skimmer. Sometimes these sticky products may even block the open chute. In this case, it is very easy to clean the chute since, compared to a pipe, it can’t be clogged. The oil skimmer is powered by Atex-certified motors. The oil skimmer is resistant to the exposure of various chemicals in the waste water streams, since it is manufactured using stainless steel. All seal types used in this skimmer are impervious to the chemicals. These seals allow the maintenance department to clean the oil skimmer using high pressure cleaners. For the past 12 months, this FRIESS Oil Skimmer has been working trouble free, and without maintenance.

The Result

Compared with the previous use of the belt oil skimmer system, the FRIESS Oil Skimmer oil / water separation equipment is more precise in operation. Instead of only covering ¼ of the tank’s surface, the FRIESS Oil Skimmer covers, and removes oil from the whole tank surface. Maintenance costs for the oil skimmer system have gone from 3,068 € per year for the previously used belt oil skimmer system, to 0 € per year for the FRIESS Oil Skimmer system.