Cleaning of hydraulic oil in the automotive industry

A big European car manufacturer operates three factories for manufacturing gear boxes for passenger cars. One of the three factories in mid-Europe uses approx. 10,000 l hydraulic oil in different machines. After three years of continuous operation, malfunction of hydraulic components rose continuously.

Situation

The maintenance team examined the cause for the hydraulic failures. Different samples of the hydraulic oils were checked in the own laboratory. The laboratory reports showed, that the number of particles in the hydraulic oil in different machines was much higher than acceptable. The maintenance team operated several bypass filter systems and used the bypass filter systems from time to time at each hydraulic system. The laboratory reports showed, that the results of filtration were not satisfying.

Solution

The maintenance manager started an internet research in order to improve the situation. He found the homepage of FRIESS GmbH and had the idea, that electrostatic oil cleaning could improve the situation. Together with the local sales agent of FRIESS GmbH the company started a test of an electrostatic oil cleaner model D8 in the factory. One electrostatic oil cleaning machine model D8 was connected with a drum, filled with 40 l of used hydraulic oil. The cleaning time took 23 h.

Result

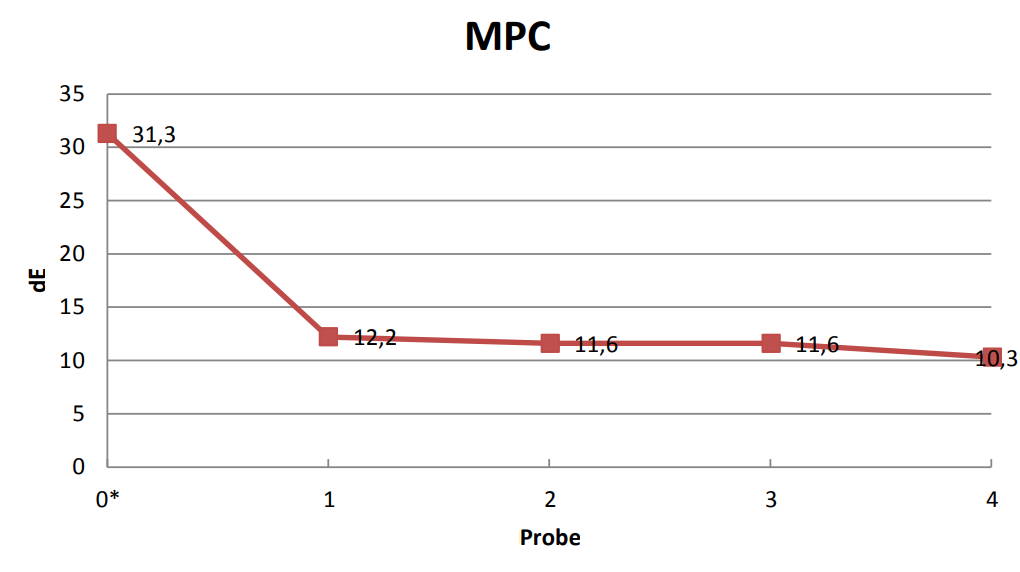

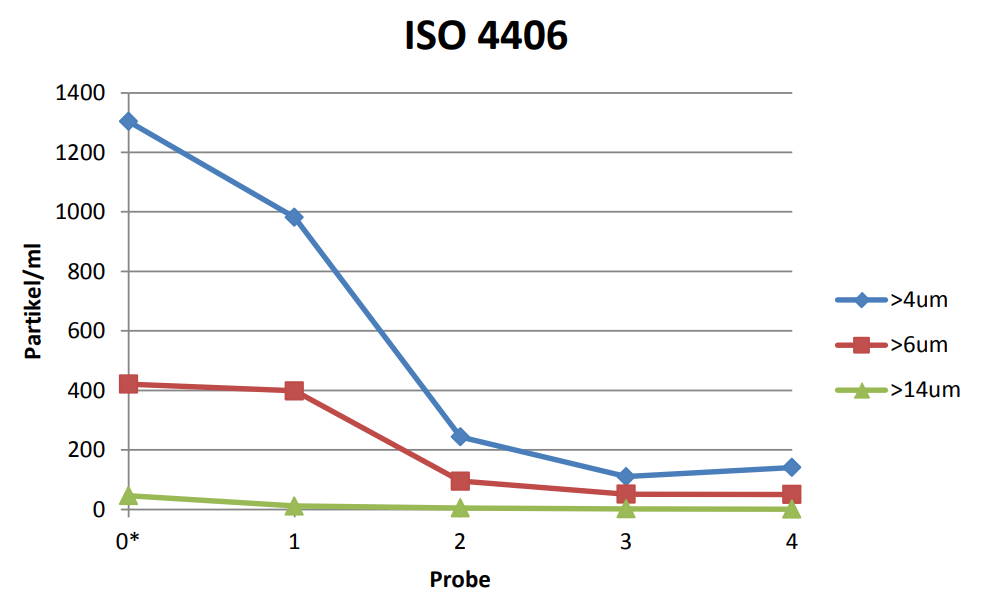

During the 23 h test period customer took samples every 6 h. The samples were checked in the own laboratory. The particle count shows values as follows.

| Sample | Date | Sample/Time | MPC[dE] | Particle count / ml ISO 4406 (1999) | ||

| >4 µm | >6 µm | >14 µm | ||||

| 0* | 14.01.2015 | 10:00 | 31,3 | 1,304.3 | 420.9 | 46.2 |

| 1 | 14.01.2015 | 16:00 | 12,2 | 981.8 | 398.5 | 11.2 |

| 2 | 14.01.2015 | 22:00 | 11,6 | 243.6 | 95.1 | 4.9 |

| 3 | 15.01.2015 | 04:00 | 11,6 | 110.2 | 51.3 | 1.8 |

| 4 | 15.01.2015 | 09:00 | 10,3 | 140.9 | 50 | 0.6 |

* Sample was taken 10 min after start of electrostatic oil cleaning machine

The particle count shows clearly, that the number of particles >4 µm was reduced by 90 % because of electrostatic oil cleaning. 80 % of malfunction in a hydraulic system is caused by dirt particles in the hydraulic system. The test result makes clear, that the operation of an electrostatic oil cleaning machine will prevent 60 % – 70 % of hydraulic malfunction.

MPC test

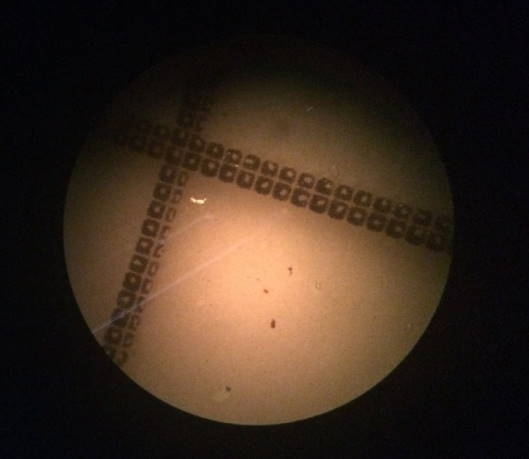

In parallel the laboratory did an MPC test (Membrane Patch Colorimetry). The MPC test means, that 50 ml of hydraulic oil will be mixed with 50 ml cleaning solvent. The mixture is sucked through a membrane with a pore size of 0.45 µm. As the result you can see oxydation product sludge and sticky resins on the surface of the membrane.

Reduction of resins and oxydation products during cleaning process

The electrostatic oil cleaner model D8 reduced resins, oxydation product and sludge by more than 60 %. Because of the separation of the resins and oxydation products and the dirt particles in the oil, the clean oil can be used after cleaning without any restrictions. Oil change is not any longer necessary. Malfunction of the hydraulic system is reduced.