Electrostatic oil cleaning machine used in a steel factory Hydraulic system with electrostatic oil cleaner model D8

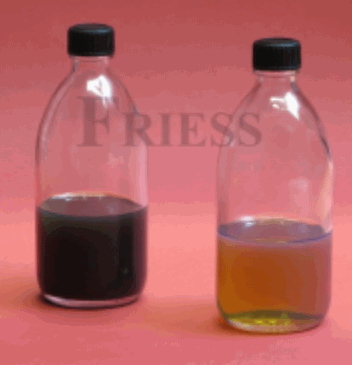

Before start up FRIESS sales manager took a sample of the hydraulic oil. After 300 h of operation of the electrostatic oil cleaning machine model D8 the FRIESS sales manager took a second sample. The direct comparison of the two oil samples shows the dramatic improvement of cleanliness. Before cleaning the oil with the electrostatic oil cleaning machine model D8 the oil was dark and nontransparent. After cleaning the oil was transparent and clear. The analysis from a laboratory confirmed the cleanliness of oil without restrictions. After cleaning the hydraulic oil is in a much better condition and can remain in the hydraulic system without oil change.

Situation

A steel factory operates two big hydraulic systems in one hall. In the first station the produced steel billets, dimensions approx. 100 mm x 100 mm, are straightened. The hydraulic cylinder, which is used to straighten the billets, is driven by a hydraulic system, manufactured by Rexroth company. In the second station the steel billets are rough grinded in order to remove scale. Because of the grinding process the entire area is contaminated with dust although the company uses an exhaust system. The hydraulic oil in both hydraulic systems is extremely dirty because of the dust in the air and in the hall, although the company uses high class seals and controls the air filter on the hydraulic tank regularly. The oil had to be changed every two months.

The maintenance department of the company carried out a lot of tests in order to improve the situation. In a first step they improved the exhaust system in order to reduce the number of dust particles in the building. In addition to that they mounted better air filter on the hydraulic tank. In a third step they started to change the seals of the hydraulic cylinder before they showed some wear. At the end all activities did not show the desired results. The maintenance team collected information’s about different filtration systems and other possibilities in order to keep the hydraulic oil clean.

Hydraulic system for straightening press

Solution

Because of positive feedback from several owners of FRIESS electrostatic oil cleaning machines they decided to test the electrostatic oil cleaning machine model D8 at their hydraulic system.

Hydraulic system with electrostatic oil cleaner model D8

Result

1. before cleaning 300 h cleaning time

2. Sample of oil Sample of oil after

Before start up FRIESS sales manager took a sample of the hydraulic oil. After 300 h of operation of the electrostatic oil cleaning machine model D8 the FRIESS sales manager took a second sample. The direct comparison of the two oil samples shows the dramatic improvement of cleanliness. Before cleaning the oil with the electrostatic oil cleaning machine model D8 the oil was dark and nontransparent. After cleaning the oil was transparent and clear. The analysis from a laboratory confirmed the cleanliness of oil without restrictions. After cleaning the hydraulic oil is in a much better condition and can remain in the hydraulic system without oil change.

- Because of continuous cleaning of the oil with the electrostatic oil cleaner model D8 the regular oil change is no longer necessary.

- The lifetime of the hydraulic oil was improved from 2 months to several years. In addition to that the malfunction of the hydraulic system was reduced by 70 %.