Tramp oil on cooling water

The cooling water in a steel plant is contaminated with oil, fat and scale. In a settling basin, most of the scale sinks to the bottom of the basin. Oil, fat and a small percentage of scale floats on the water surface.

Situation

A scraper moves the scale on the bottom of the basin towards a mud collection tank. From this mud collection tank, the scale is removed by an excavator. The floating oil is collected at a baffle. The water floats underneath the baffle into the next chamber of the basin. Three pumps are mounted in this chamber and pump the cleaned water back into the cooling circulation. On the surface of the water in front of the baffle float fat, lubrication oil, hydraulic oil mixed with dust, dirt and scale. In order to keep the running cost as low as possible, the amount of water in the separated waste oil should be less than 5%. The whole separation system is mounted outside and should run the whole year.

Solution

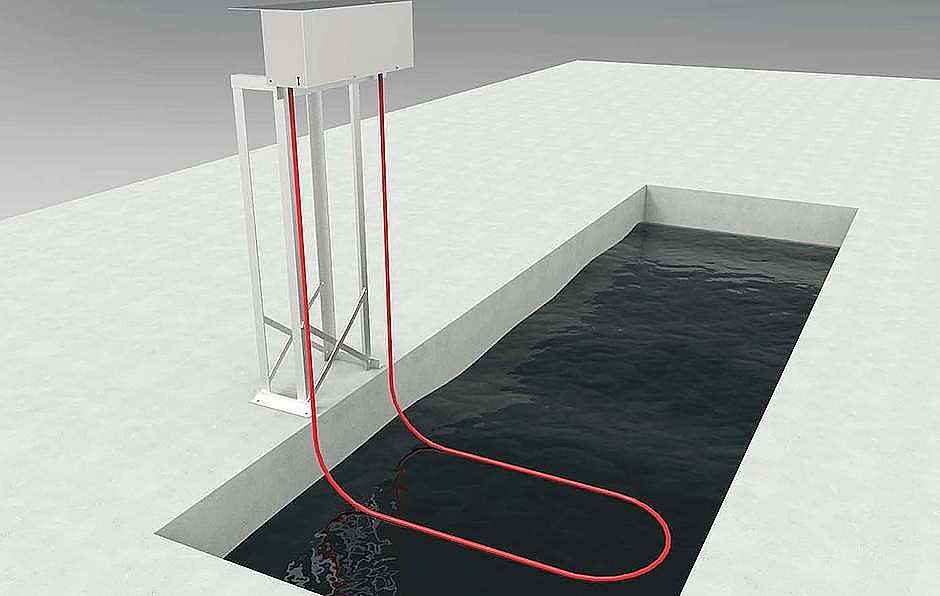

To remove the oil from the whole surface of the basin, the customer decided to install an Oil Skimmer with oil collector tube. To reach the whole surface with the oil collector tube, a tube guide was installed. The skimmer runs 24 hours/day in order to clean the water as good as possible. The oil and small amounts of water, which are delivered by the Oil Skimmer, float into a decanter. The water settles at the bottom of the decanter, while the oil floats on top. The oil floats over a weir into the oil collecting tank, while the water floats back into the cooling water basin. With an electronic speed control, the capacity of the Oil Skimmer is adjusted to the amount of oil on the water surface. Additional protection contacts make sure, that the motor does not become too hot at low speed. To operate the Oil Skimmer in winter times, the Oil Skimmer, the oil chute and the decanter tank are heated. The heating starts at temperatures lower than 3 °C. The level in the oil collecting tank is continuously controlled. When the oil level reaches the maximum level of the oil collecting tank, the Oil Skimmer is switched off and an alarm is shown on the central switchboard of the factory.

FRIESS Oil Skimmer S100

FRIESS Oil Skimmer S100

Connected oil tank

Connected oil tank

Result

The continuous operation of the Oil Skimmer make sure, that there is no oil on the cooling water. The cooling water quality fulfills the needs of the plant. The electronic control of the oil skimming system enables a 24 hour automatic operation without manual control.