Oil and Graphite Removal from cooling waterat a Crankshaft Forging Company using FRIESS Model W40 Oil Skimmers

A well-known German Company that manufactures crankshafts for gasoline and diesel engines had ordered a new drop-forging press from a Japanese manufacturer. After the forging press foundation had been constructed, the Japanese manufacturer installed the complete drop-forging press line, as well as all the ancillary equipment, so that it was a turn-key operation for the buyer.

To cool the hot forging die, an emulsion of water and graphite is sprayed into the forging die, which serves to lubricate the die and also prevents the parts from sticking in the die. Some of this water immediately vaporizes in the hot forging die, leaving the deposited graphite to act as the die lubricant. The small quantity of water that doesn’t vaporize, flows from the forging die into a waste water collecting tank, which is located a floor below the forging press. Oil from leaks, graphite, and lubricating oil will also flow into the waste water collecting tank.

This oil-water emulsion is pumped from the collection tank by a submerged pump into two separate waste water tanks that have a 30 cubic meter capacity, located about 20 m away from the forging press line. The water is collected for several days in alternate waste water collecting tanks. This settling time allows the emulsified oil to float to the surface.

The Requirement

The manufacturer of the forging press line needed a system that could remove the floating oil, mixed with graphite and scale, from the surface of the waste water. The oil removal system should be able to function fully automatically and without maintenance. The estimated amount of lubricating oil that had to be removed from the waste water was 1,000 liters, in 20 days of operation.

Each waste water tank would be equipped with an oil skimmer removal system, and with a portable waste oil collection tank. Both waste water tanks were required to be double walled tanks, equipped with leak detection equipment, and liquid level controls, to prevent possible environmental damage. With very tight space limitations for the installation of the waste water tanks, the manufacturer of the drop-forging press line had very specific specifications for the design and construction of all these components.

The German crankshaft forging company, having had positive experiences with several, previously installed FRIESS Oil Skimmers systems, recommend that the Japanese forging press manufacturer contact FRIESS GmbH for the oil skimmers.

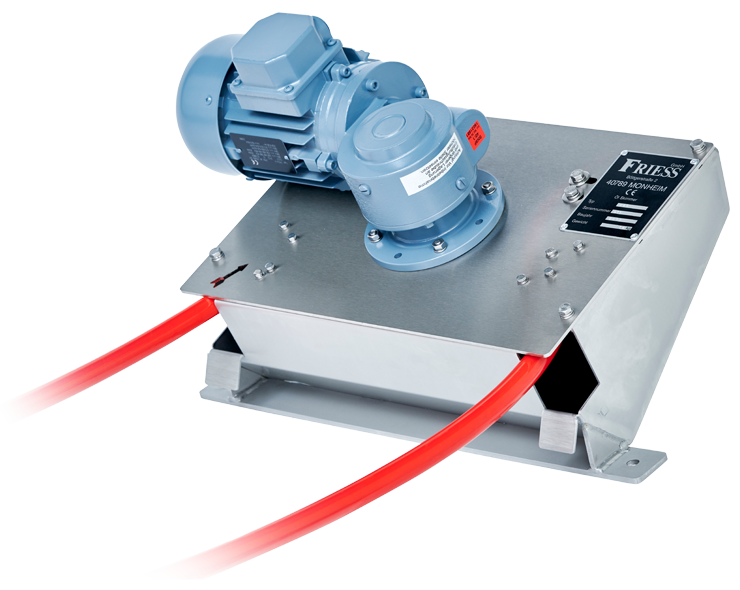

The solution: FRIESS Model W40 Oil Skimmer

The space available for the installation of the waste water collection tanks in the manufacturing building was very limited, because of the building construction. The original design plan called for the installation of two waste water tanks with a combined capacity of 40 cubic meters of water, using two tanks of different sizes. Because of the installation space constraints, the total volume of the two waste water tanks was reduced to 30 cubic meters.

To remove the oil and sludge from the water surface, each tank was equipped with a FRIESS Model W40 Oil Skimmer with floating oil collector tube and tube guides. The floating oil collector tube’s motion on the water surface removes the oily sludge from all corners of the tanks. The oil and sludge that is removed by the collector tube is scraped off the tube by the ceramic scrapers. This oil, mixed with graphite and scale, goes into the closed, one cubic meter capacity waste oil collecting tank.

When an upper limit of waste oil and sludge in the waste oil collecting tank is reached, limit switches shut off the oil skimmer, and a message is shown on the touch screen of the oil skimmer control unit. The maintenance department now has sufficient time to pump the waste oil into their disposal truck. The liquid level in both waste water tanks is controlled by min – max level switches. Once a maximum liquid level has been reached, no more waste water containing oil and sludge is pumped into the waste water tank. The tank is emptied into a special truck using a suction hose.