How does the FMF Magnetic Filter help you?

Especially during grinding, honing and lapping, ferritic particles can get between the tool and the workpiece, affecting surface quality and stock removal rates.

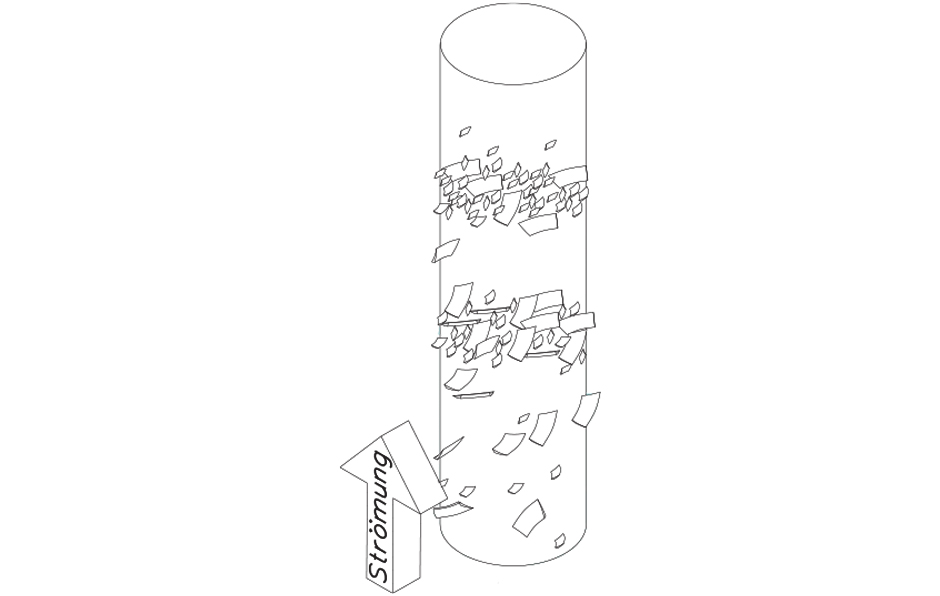

With one, three or six concentrically arranged Magnetic Filter rods, the field strength attracts the particles to the Magnetic Filter rods and holds them there. The process is particularly popular because the magnetic filters require no consumables or additional energy. Therefore, no additional operating costs occur.

Cleaning is just as simple: Simply wipe off the dirt and recycle the particles. So the process is also environmentally friendly and sustainable!

FMF 240/1

Max. flow rate: 70 l/min

Temperature range: 5 °C bis 60 °C

Dirt capacity: 0,6 kg

Max. operating pressure: 15 bar

Connection: 3/4″ BSP

FMF 310/1

Max. flow rate: 100 l/min

Temperature range: 5 °C bis 60 °C

Dirt capacity: 0,8 kg

Max. operating pressure: 15 bar

Connection: 1″ BSP

FMF 310/3

Max. flow rate: 150 l/min

Temperature range: 5 °C bis 60 °C

Dirt capacity: 2,4 kg

Max. operating pressure: 15 bar

Connection: 1 1/2″ BSP

FMF 420/3

Max. flow rate: 250 l/min

Temperature range: 5 °C bis 60 °C

Dirt capacity: 3,0 kg

Max. operating pressure: 15 bar

Connection: 1 1/2″ BSP

FMF 420/6

Max. flow rate: 500 l/min

Temperature range: 5 °C bis 60 °C

Dirt capacity: 6,0 kg

Max. operating pressure: 10 bar

Connection: 2 1/2″ BSP