The FRIESS Magnetic Filter ASMF not only removes iron, steel and stainless steel particles from all kinds of process fluids, but can also clean itself. As a fully automated system, it therefore proves particularly useful at all locations where few personnel can be deployed.

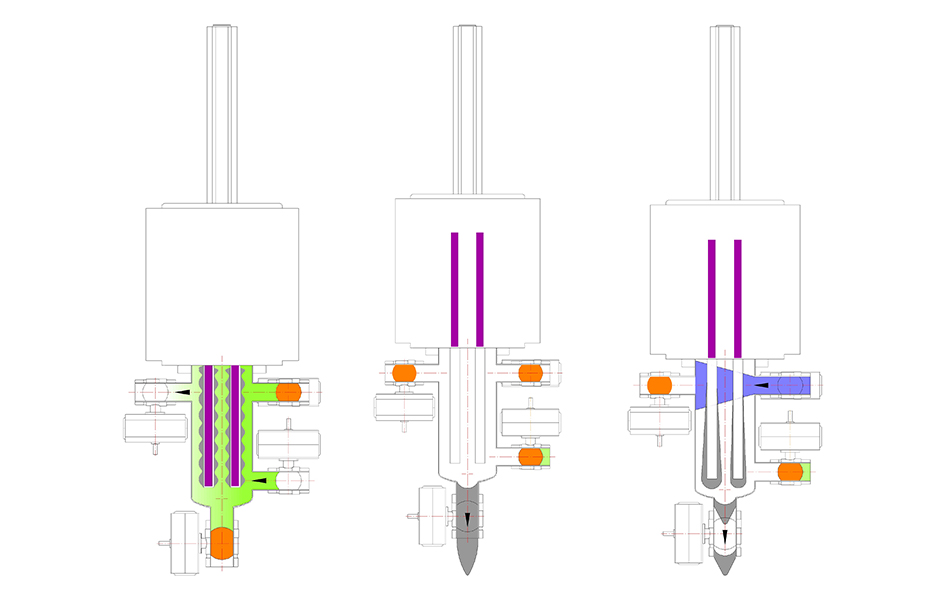

As a Magnetic Filter, it is designed to clean liquids of ferritic dirt particles in particular. These can be particularly small, in some cases down to less than 1 µm, and can be reliably attracted thanks to the magnet. For this purpose, the magnetic filter rods with their neodymium magnets inside create a strong magnetic field that effortlessly attracts the particles. The ASMF Magnetic Filter is equipped with three or five concentrically arranged magnetic filter rods.

The process is particularly popular because the Magnetic Filters require no additional consumables and only a minimal supply of energy. Virtually no further operating costs accrue.

ASMF 3

Max. flow rate: 150 l/min (water)

Max. flow rate: 75 l/min (oil)

Temperature range: 5 °C to 60 °C

Dirt holding capacity: approx. 2 kg

Max. Operating pressure: 10 bar

Connection: 1 ”

ASMF 5

Max. flow rate: 300 l/min (water)

Max. flow rate: 150 l/min (oil)

Temperature range: 5 °C to 60 °C

Dirt holding capacity: approx. 5 kg

Max. Operating pressure: 10 bar

Connection: 1 1/2″